The news has likely reached everyone: in 2024, vanadium flow batteries turn 40 years old.

From left to right in the picture: Franz Grossmith, Maria Skyllas-Kazacos, Michael Kazacos, Miron Rychcik.

It all began in 1984 with the first experiments conducted by Honours Thesis student Elaine Sum (who later completed her PhD in aluminium smelting) at the University of New South Wales, Australia (UNSW).

The main celebration of this milestone took place at UNSW Sydney on 15-16 October, during the “Symposium on the 40th Anniversary of the Invention of VFB Technology,” where Anthony Price was also honoured to present online.

The “afterparty” was organised by Flow Batteries Europe (FBE), which last week held a webinar titled “Vanadium Flow Batteries: 40th Anniversary Webinar” (click here to view the recording). The session featured an exclusive interview with Emeritus Professor Maria Skyllas-Kazacos AM, the original developer of the vanadium flow battery at the University of New South Wales.

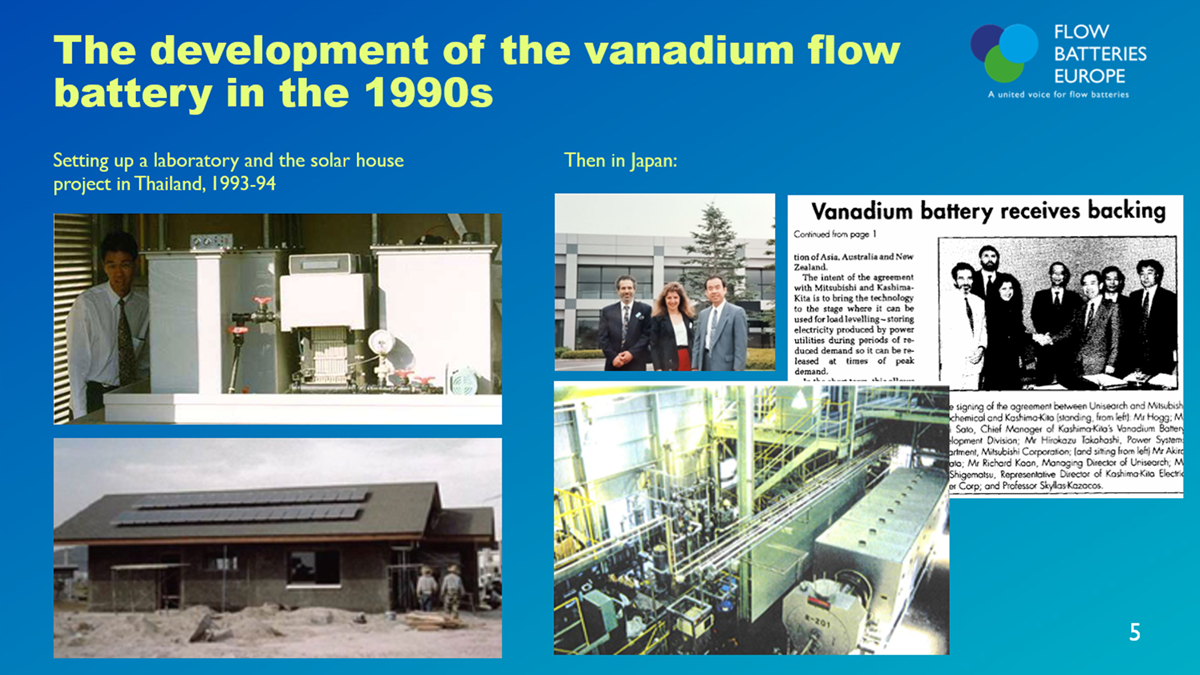

Over 120 participants attended the online event, which explored the historical development and major advancements of this pivotal technology, tracing its journey from inception to its current impact. During the discussion, Professor Skyllas-Kazacos detailed the development of the VFB and highlighted the challenges faced during research, particularly with electrolyte solubility and electrode performance. She also shared insights on securing funding, and the interest shown by the Australian government to support renewable energy projects in remote areas.

When asked about funding, Professor Skyllas-Kazacos admitted, “Surprisingly, back in those days, it was rather straightforward to persuade people and receive funding from the government, which led to commercialisation.” Companies began approaching the University to negotiate licenses in the early 1990s, providing additional funding for further projects and electrolyte development. The situation changed in the early 2000s. You’ll need to watch the full webinar to find out why!

GLOBAL VANADIUM SUPPLY

The webinar then turned its focus to the global vanadium supply chain, where Dr. Jana Plananska from Norge Mining spoke about the vanadium mining industry in Europe and the growing demand of vanadium worldwide. She pointed out that nearly 80% of global supply of vanadium comes from Russia and China, leaving Europe nearly completely reliant on these imports.

She reiterated the importance of establishing vanadium projects/supply chains in Europe which will come with significant costs and political considerations. Dr. Plananska pointed to Norge Mining project in Norway, which aims to produce magnetite concentrate – a precursor for vanadium oxide – by 2029, and emphasised the need for additional funding and support to bring these initiatives to fruition.

VANADIUM FLOW BATTERY PROJECTS

Our discussion turned from the global supply chain to the remarkable advancements in vanadium flow battery technology. Vanadium flow batteries are emerging as a powerful solution, especially in sectors such as military bases, mining, and remote communities which are shifting towards decarbonisation.

Dr. Thomas Lüth from CellCube spoke about a high-altitude vanadium flow battery project in the Rocky Mountains situated near a military base in Bridgeport, Wyoming. The military base, which currently relies heavily on diesel due to its weak infrastructure and winter conditions, aims to enhance its renewable energy integration, including existing solar installations.

MORE AUTOMATION IS NEEDED IN THE MANUFACTURING PROCESS

Dr. Lüth went on to discuss manufacturing flow batteries, noting that many are still assembled by hand. This labour-intensive process, while effective, has room for substantial improvements through automation. This would streamline production, boost efficiency, and ultimately reduce costs – critical steps in meeting the rising demand for long-duration energy storage across Europe.

Over the last 40 years, VFB progressed from the first 1kW battery built at UNSW to large-scale systems now deployed worldwide. To further advance VFB in Europe, we need to build the security of the supply chain and automate elements of the manufacturing process to reduce the cost and time to deploy VFB.

Click here to watch the full webinar!

We hope you remember that next year, the IFBF is heading to Vienna for its 2025 edition and see manufacturing at CellCube, our host for 2025. Be sure to have 24–26 June 2025 already marked in your calendar!